The Marker

Laser Modeling Israel- The One Stop Shop for engineering services in research and development processes. Unlimited engineering freedom, incredibly precise production capacity and a diverse and special arsenal of materials. Laser Modeling presents the forefront of innovation in the field, using world-leading breakthrough technologies

The Marker

The 3D world is currently transitioning from model production to series production, marking the advent of the Industry 4.0 era. This transformation is being driven by cutting-edge advancements in materials, robotics, artificial intelligence, and machine learning. As a result, 3D printing is poised to revolutionize various fields including medicine, engineering, and security. In Israel, Laser Modeling stands at the forefront of the next wave of 3D manufacturing processes, spearheading innovation and progress.

Plastic Time

Laser Modeling Israel specializes in the production and printing of small and medium-sized production series in 3D Printed. Recently, the company had introduced a new capability: TPU mass production in HP’s new powder printers. Do you also work with TPU? Let yourself be impressed by LMI’s capabilities

Plastic Time

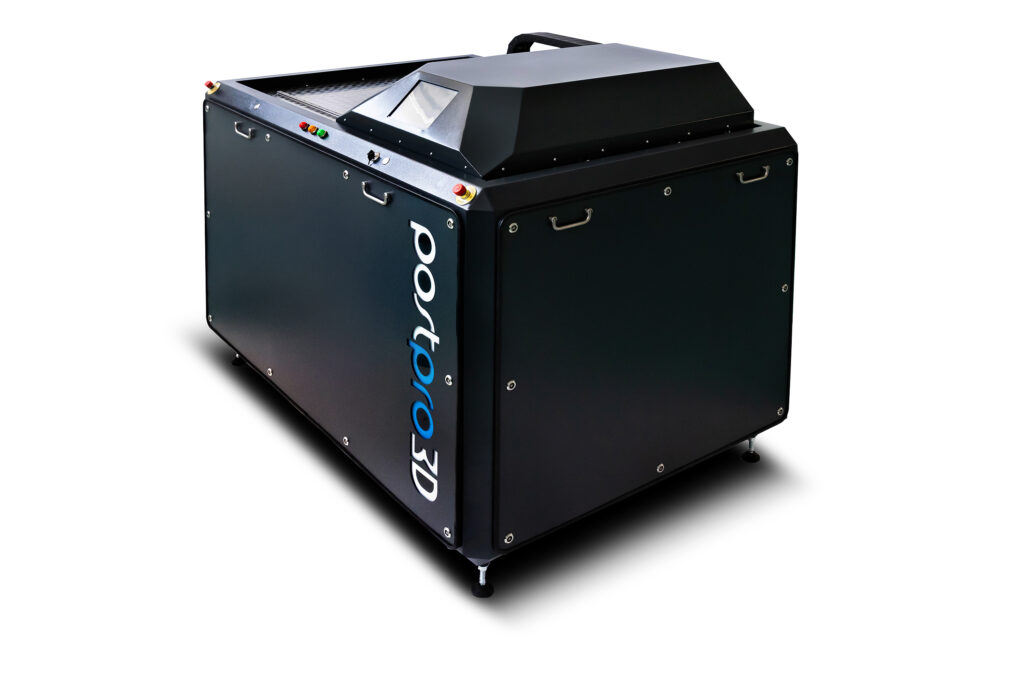

LMI recently purchased the AMT PostPro machine that supports the final finish of 3D printed polymer parts. This innovative technology gives the surface the look and feel of an injected part, polishes and refines both exterior and interior surfaces, in less than two hours work cycle time

BeChadrei Charedim

Forming a bridge between 1000-year-old Jewish ancient tradition, and the groundbreaking Israeli start-up nation. YouDaica (Powered by Laser Modeling Israel) main and unique advantage is our ability to fully personalize each and every design for our customers, to a level that was unattainable and unimaginable- until now. YouDaica is the world’s first company to set out on this amazing journey of bringing the deepest Jewish values and beliefs to life.

Channel 14, Israel

Everyone seems to already know that today everything can be produced with the use of 3D printing . From aircraft parts, through medical equipment to day to day tools . Another interesting and surprising use for this phenomenal technology is rather an unconventional field: Jewish art. Stratasys, a company that specializes in 3D printing solutions, created a special competition for Hanukkah and initiated a spinning top design competition. The company has collaborated with YouDaica (Powered by Laser Modeling Israel), a company that produces Jewish art, printed in 3D Printers

Walla News

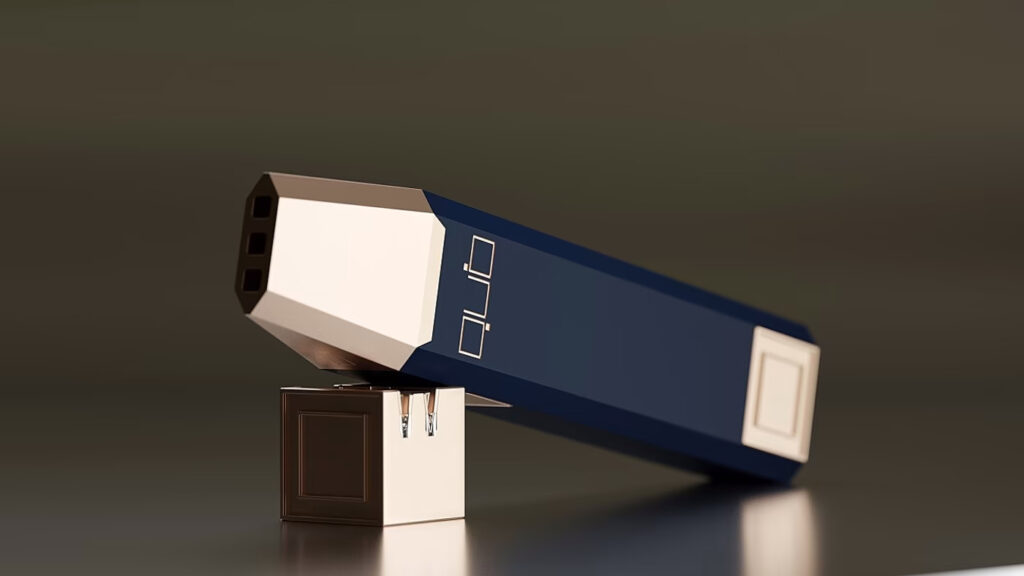

Aim for more: reduce the harm from smoking cannabis. The US cannabis market is rolling in $ 17 billion a year and an Israeli startup from Ness Ziona is trying to take part in the celebration, with the help of an inhalation product.

3D Printing Industry

3D printed anatomical models developed by rapid prototyping service provider Laser Modelling Israel (LMI) have aided surgeons in a complex segmentation surgery for conjoined twins.

Maariv

Results in just one minute: Israeli researchers have developed a breath test for corona. Researchers at Ben-Gurion University in collaboration with Laser Modeling Israel have developed the “owl,” which ensures a high level of accuracy for detecting carriers of the virus. The test may help monitor carriers at airports, factories, and large companies

Plastic Time

New addition to LMI’s technological arsenal- Stratasys Fortus 900 FDM printer. This unique FDM printer can print parts up to 900X600X900 mm in volume. It is also used for industrial printing of a large variety of smaller parts in one production round. All with no less than 14 materials including engineering plastics for industrial applications, thar are durable To solvents, acids and bases.

Plastic Time

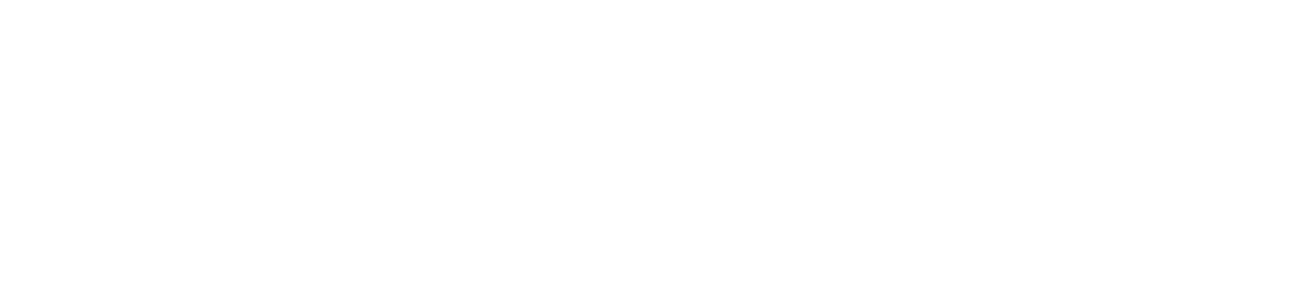

What is the most cost-effective way to produce in small series? LMI offers many services, among them are the silicone molds, that combine two technologies: 3D printing that allows the production of a master model that is accurately copied into a mold, and vacuum chambers for mixing and pouring the materials into the mold. This combination results in high quality parts that are obtained at a price and at a production rate that supports rapid development for all manufacturing purposes and domains