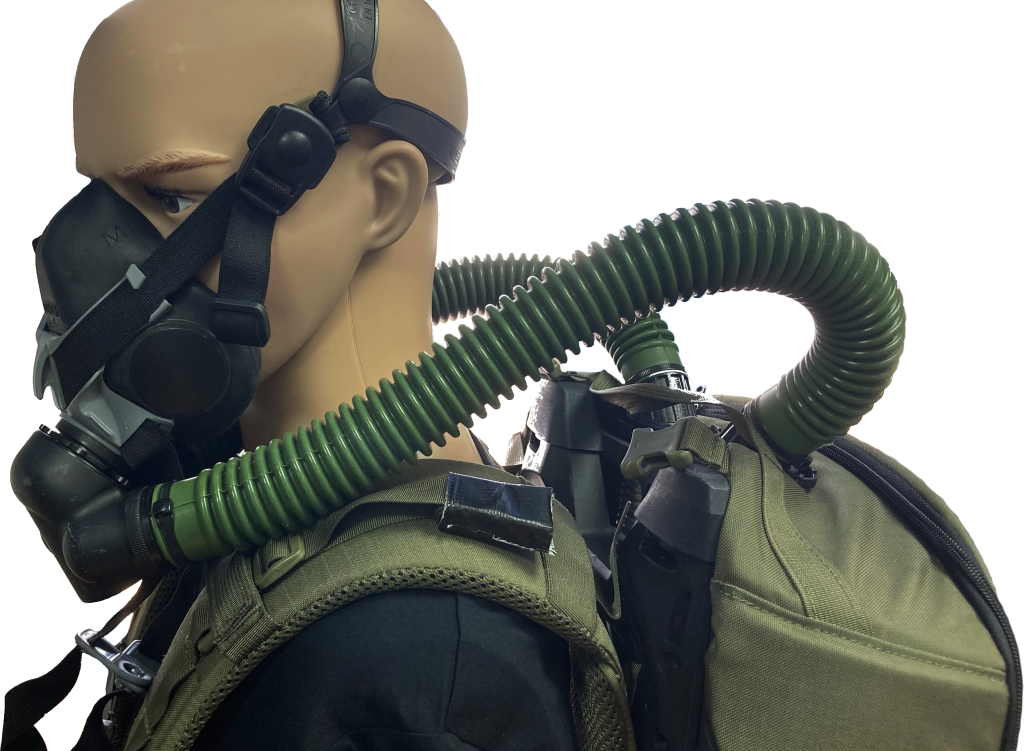

The Perfect Fit for the Military Domain

The military has some of the toughest industry performance standards in the industrial world. The demand and need to produce complex yet lightweight parts and products are paramount. Militaries have taken advantage of 3D printing to save costs, speed-up production and enable innovative design. Laser Modeling Israel is uniquely positioned to meet the challenges with our experienced team and high-performance materials.

When approaching a military grade challenge, all our in-house technologies become highly relevant to create the perfect fit for the different military application. 3D printing could provide the precision needed for the military standard, while allowing weight reduction and material firmness. Using the FDM technology, precision could go up to 0.1 micron in layer width, even in industrial grade materials such as Ultem 1010 and Ultem 9085. Our printing resolution does not stop at that, and alongside our FDM printers, our HP MJF printers bring us to an astonishing precision of 0.8 micron in layer width.

Size is also a crucial aspect when discussing military grade prototypes and models. Therefore, we have expanded our arsenal and included two Stratasys Fortus 900, the most advanced FDM printer in the world, giving us the option to print, using 8 different materials, in a size that goes up to 900X600X900 mm. Another option is to print with the MJF printers, that reach a size of 380X280X380 mm, while providing us rapid production abilities.

Military grade equipment also requires versatility in color, texture, and transparency. To answer these demands, we offer you our in-house Polyjet technology, that brings forward the option to create fully transparent, glass-like models, alongside models that could be in any color in the spectrum (excluding metallic ones). Polyjet printing technology could also perfectly mimic natural textures to create better grip for functional gear, or for camouflage purposes.

Lastly, we offer more relevant services, such as 4 axis CNC machinery for any metallic parts you might need, with a processing volume of 1000 mmX500mmX400mm, and an average precision level of up to 10 Micron. Another service is offered by our silicone molds’ department, that with the combination of molds and 3D printing, provides solutions for applications that require cost-effective colorful and flexible models.